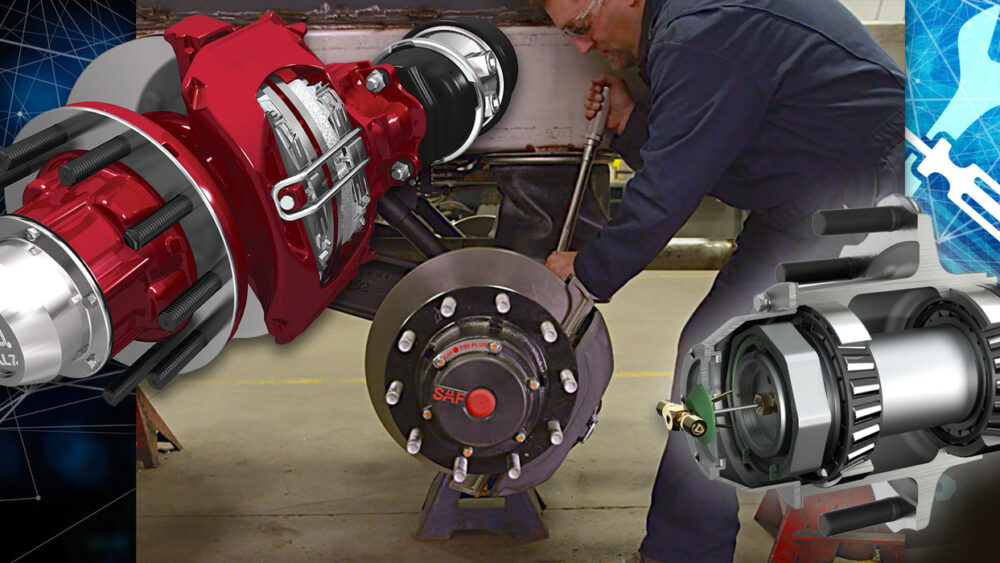

Top truck wheel end maintenance tips

Reducing overall heavy-duty truck maintenance costs plays into every decision related to wheel-end systems, noted Tony Ryan, national service manager–fleets at SAF-Holland. “For example, air disk brakes have a higher initial cost which is offset by reduced overall maintenance costs,” he said. “Premium hub/bearing/lubrication systems can reduce maintenance issues.”

Click Here to Read More

In general, the wheel-end maintenance needs for steer, drive and trailer axles are similar, said Jeff Wittlinger, general manager, trailer axle and brakes at Hendrickson. However, tools, equipment and training may vary depending on the wheel-end system, so technicians should familiarize themselves with the specific requirements for any wheel-end system for which they will be performing maintenance.

Ramses Ortiz, product manager, trailer products at Meritor, pointed out that wheel ends vary by application. “Drive axle wheel ends are typically lubricated by the lubricant in the axle, whereas in steer and trailer wheel ends, the lubricant is contained within the wheel end,” he explained. “Although wheel ends in general use similar components, in some cases, like when cartridge bearings are used, the maintenance will be different.”

For wheel-end systems to function and perform properly, it’s critical that wheel bearing adjustment is precise, noted Tom Ryan. TMC RP-618B provides detailed instructions for the proper wheel bearing adjustment.

Ryan also listed common mistakes that may occur and that can be avoided with effective service practices:

• Different spindle nut and hub/bearing types have different torque procedures. It’s important for technicians to be able to identify the different spindle nut and bearing types and be aware of the correct procedure for each type.

• There are different styles of axle spindle nuts, hubs and bearing sets available from multiple manufacturers, and they utilize different installation and torque procedures. It’s important for technicians to be knowledgeable in order to not only identify the different styles, but to also be educated on their service procedures.

• If technicians use multiple extensions on torque wrenches it can compromise achieving the correct torque.

• Spinning the wheels to seat the bearing rollers is an integral part of achieving the correct torque. If you don’t spin the wheel, the rollers don’t seat correctly against the back of the bearings and the torque is only as good as the first wheel rotation.

“Wheel-end assemblies should be inspected at regular intervals for seal leaks and smooth rotation,” said Jeff Wittlinger. “Perform a visual inspection of the hubcap and back of the hub to detect any signs of leakage. Also, rotate the wheel-end to ensure smooth and quiet rotation. If the bearings feel rough, sound noisy or do not rotate freely, the unit should not be put back into service without further review and maintenance.

Ramses Ortiz provide a list of maintenance items for wheel ends as well:

• Before any trip, look for any signs of lubrication leakage or damage, and missing or out of position components.

• Monitor lubricant level and quality. The frequency varies depending on the application. Severe duty would require more frequent inspections.

• Replace the lubricant if there are any signs of degradation and/or contamination.

• Do a walkaround following service and look for any signs of excessive heat, such as smoking, smelling, and even by touching the hub with a finger. Excessive heat on a wheel end is typically a symptom of a bearing issue.

• Look for worn, damaged, cracked or missing pieces. Especially wheel studs and nuts.

“Typically, no special tools are required to perform wheel end maintenance,” Ortiz added, “but the actual tools to be used will depend on the wheel end being worked on and the guidelines of the specific equipment supplier, as different manufacturers use different parts in their designs.”

Jeff Wittlinger also pointed out that tools, equipment and training may vary depending on the wheel-end system. As a result, some wheel-end systems may require specific tools or socket sizes, which are available from the manufacturer.

“A comprehensive maintenance program is critical for fleets to effectively track the performance of key wheel end components, especially as new equipment is introduced,” Wittlinger added. “Monitoring the performance of key components at regular intervals can help identify potential problems early.”

“Wheel ends are the connection between static and the dynamic parts in a vehicle, so proper maintenance of wheel ends helps prevent breakdowns that can escalate if left unattended,” Ramses Ortiz said. “Regular maintenance translates into increased uptime and lower cost of ownership.”